unity

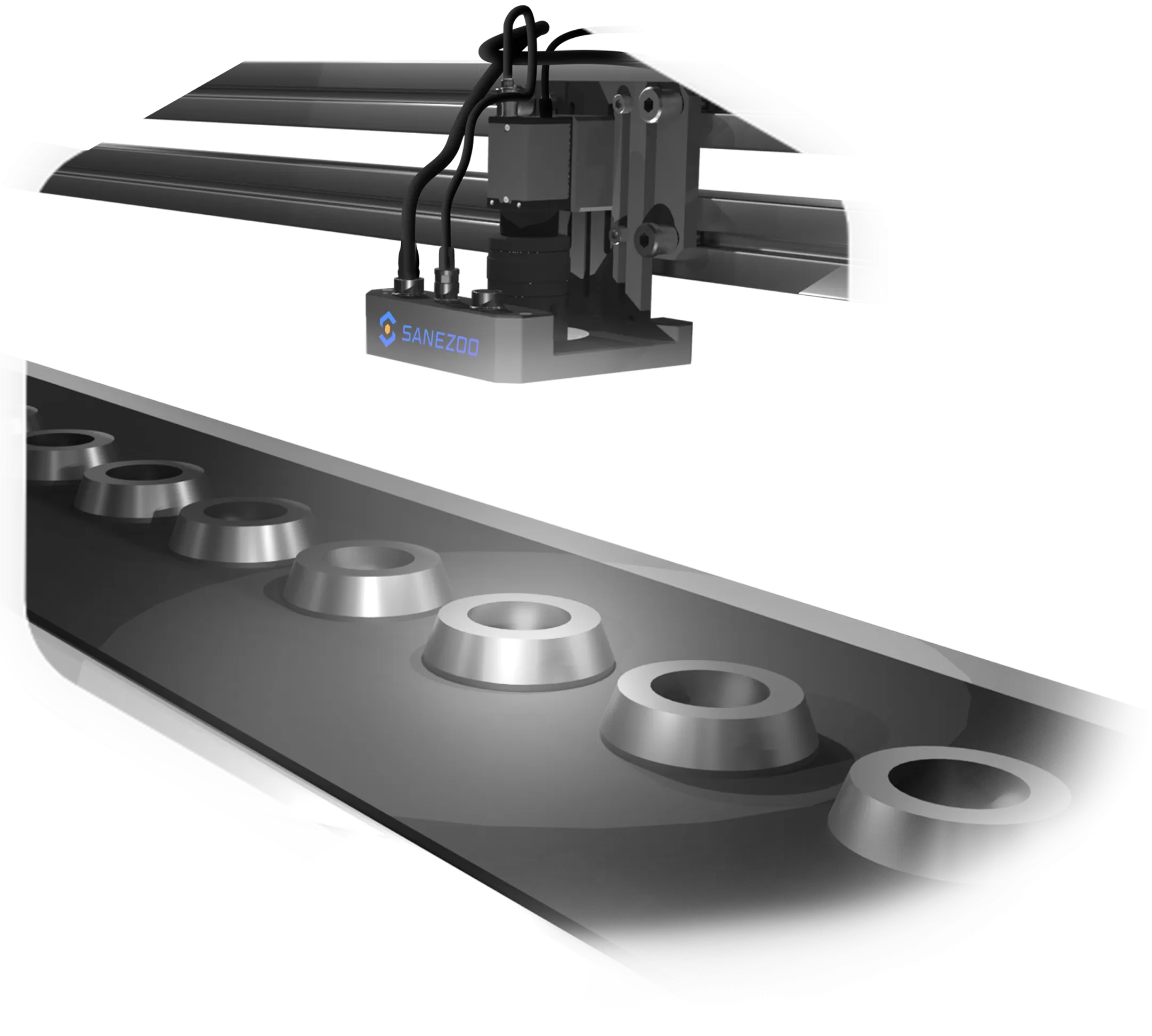

Visual Quality Control

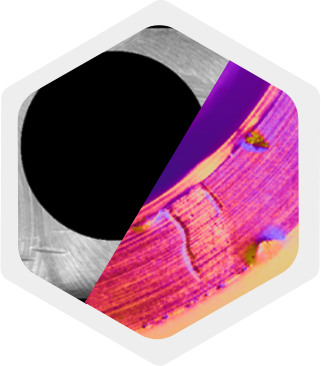

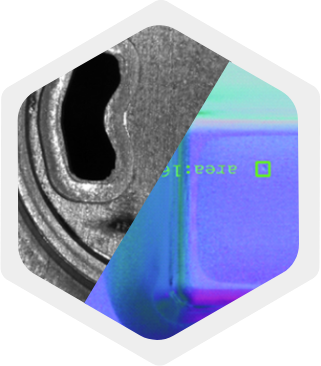

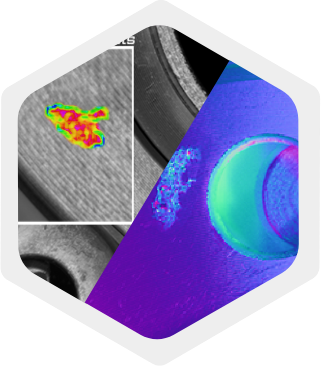

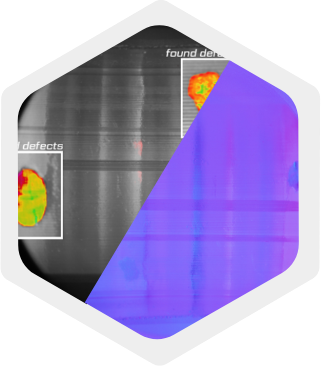

We will discover surface defects that the operator will not see. Thanks to unique technology, we capture even the most difficult to see defects that conventional 3D cameras cannot.

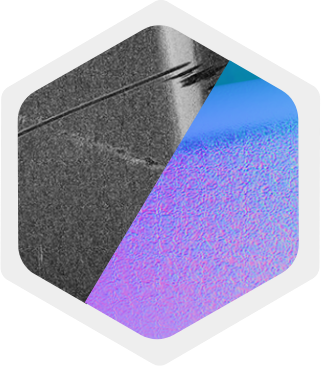

Visual inspection of even glossy and matte surfaces using unique machine vision with AI

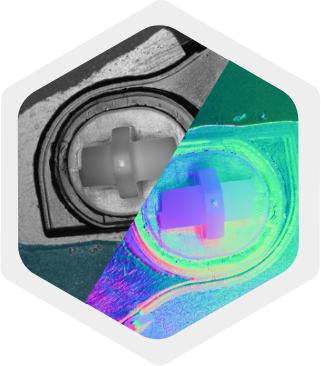

Visual inspection of even glossy and matte surfaces using unique machine vision with AI Reconstructing the fine surface of a 3D part and capturing the finest details

Reconstructing the fine surface of a 3D part and capturing the finest details 6 types of output data including a precise surface map

6 types of output data including a precise surface map

More about unity

More about unity

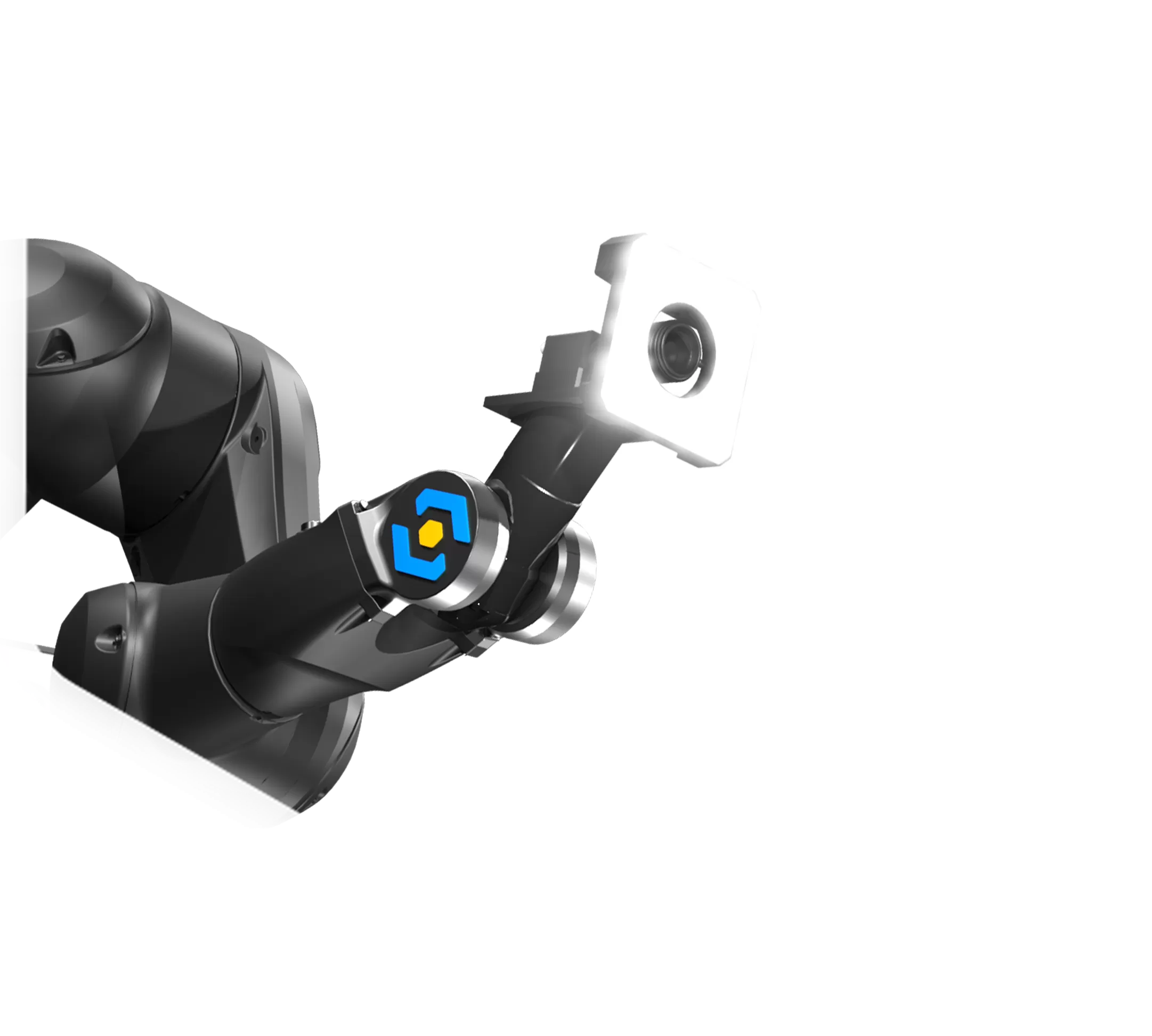

Thanks to GRASP's artificial intelligence, it performs a precise grip from the angle it needs

Thanks to GRASP's artificial intelligence, it performs a precise grip from the angle it needs Fast and instantaneous process without algorithm recalculation guarantees significant time savings

Fast and instantaneous process without algorithm recalculation guarantees significant time savings GRASP senses 3D space, learns how to move in it and avoids all obstacles

GRASP senses 3D space, learns how to move in it and avoids all obstacles

Offers complete automated inspection from diverse viewpoints, enhancing accuracy and coverage

Offers complete automated inspection from diverse viewpoints, enhancing accuracy and coverage Comprehensive inspection of intricate parts from multiple angles

Comprehensive inspection of intricate parts from multiple angles Seamless integration of cutting-edge 3D-guided robotics and advanced quality control.

Seamless integration of cutting-edge 3D-guided robotics and advanced quality control.