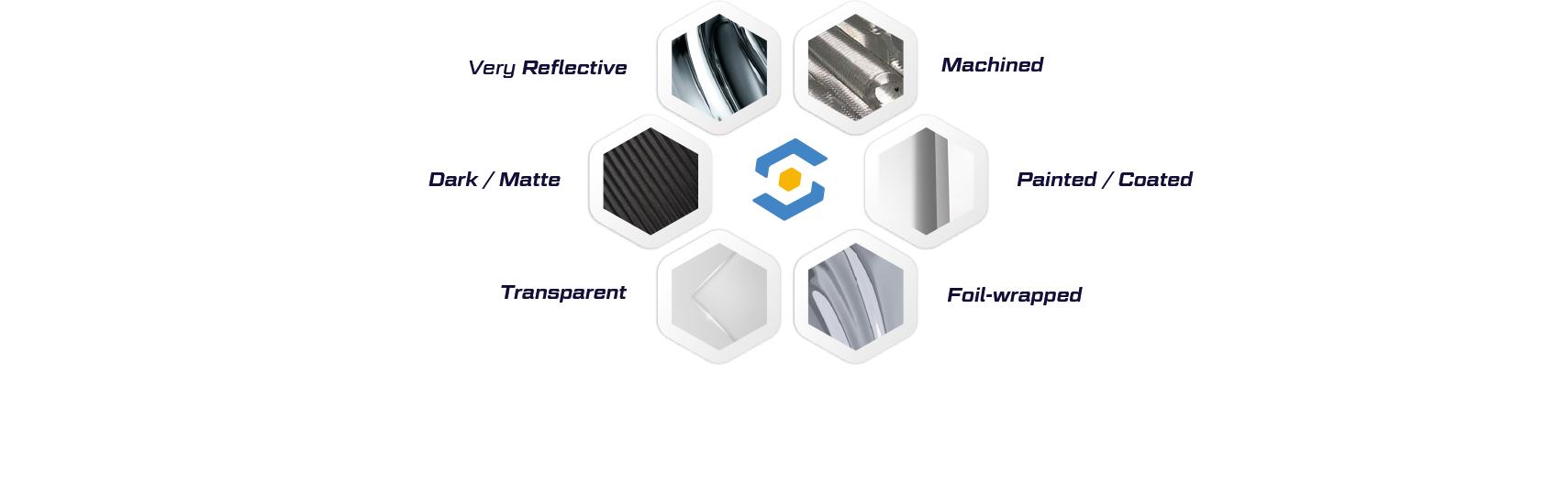

Explore the endless possibilities of SANEZOO's cutting-edge technologies, designed to revolutionize various industries.

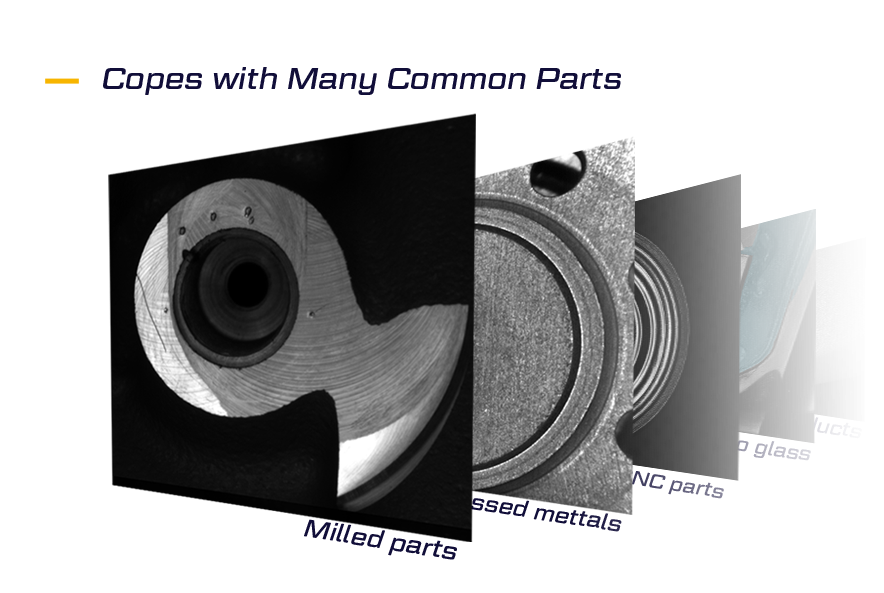

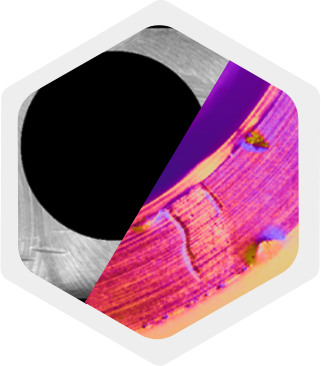

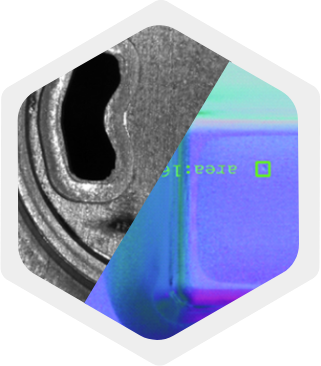

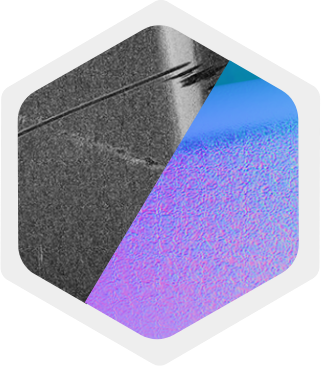

From automotive manufacturing to aerospace, our advanced solutions redefine precision, efficiency, and quality in diverse applications. Discover how our innovative products elevate production lines, enhance quality control, and automate complex inspection tasks with unparalleled accuracy and speed.

Unleash the power of SANEZOO solutions to optimize your manufacturing processes and redefine industry standards.