Flawless Defect Detection on Transparent Surfaces

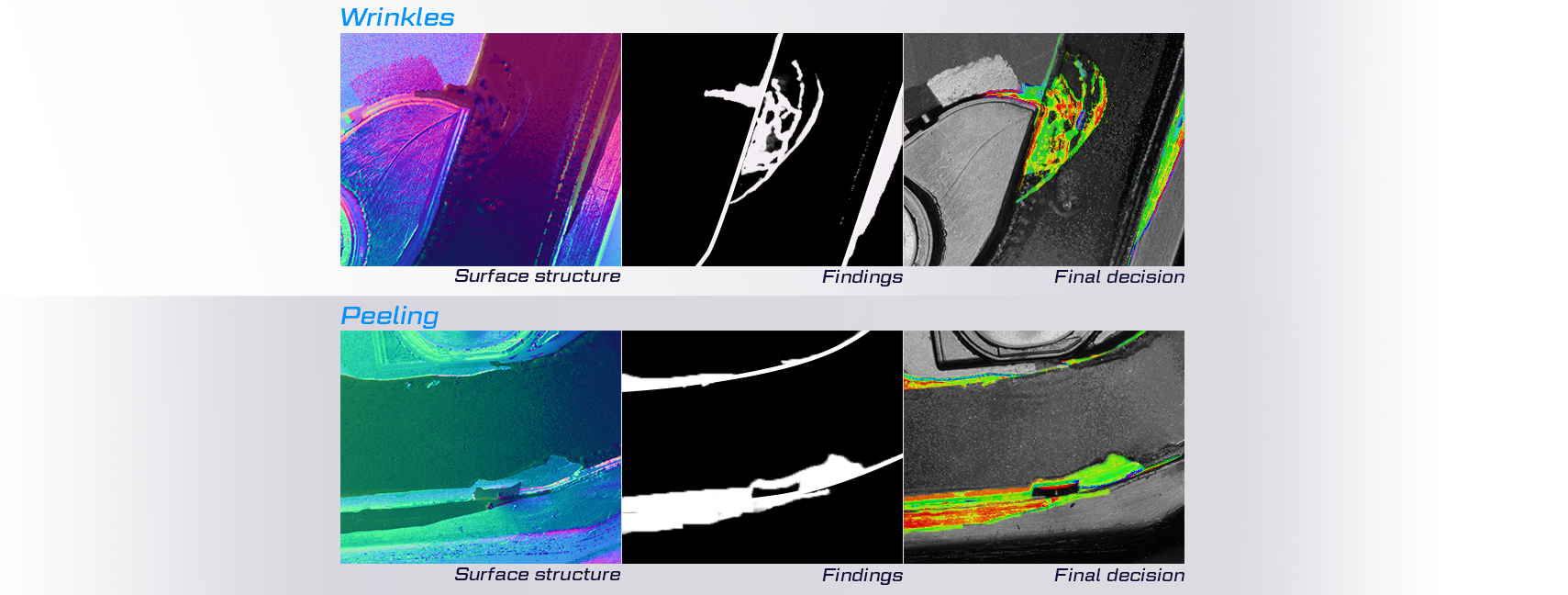

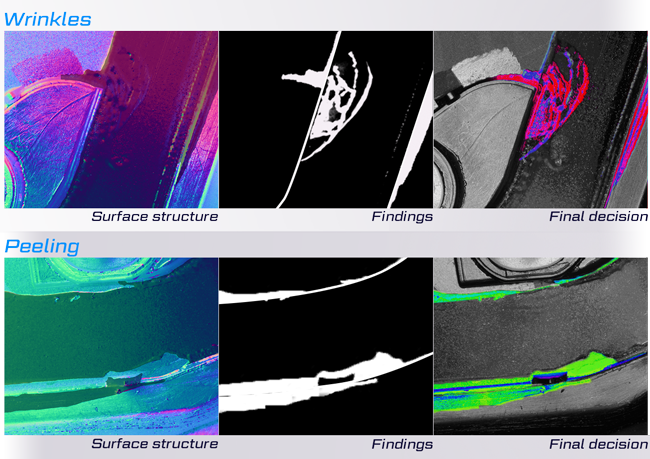

Challenges in defect detection on glass and materials applied to glass primarily stem from their transparency, which can make defects less visible.

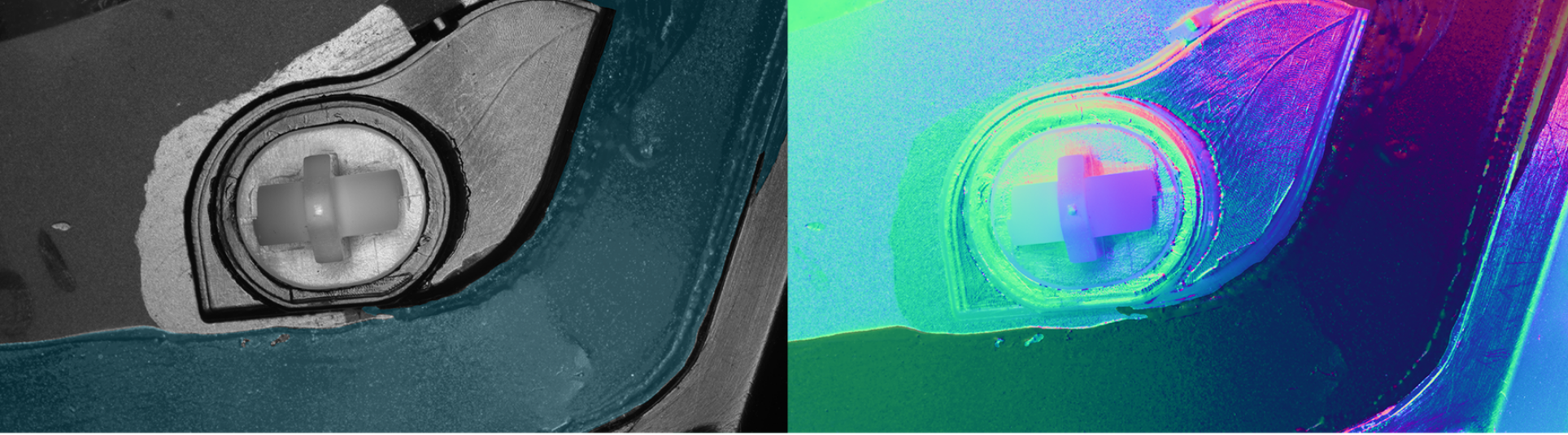

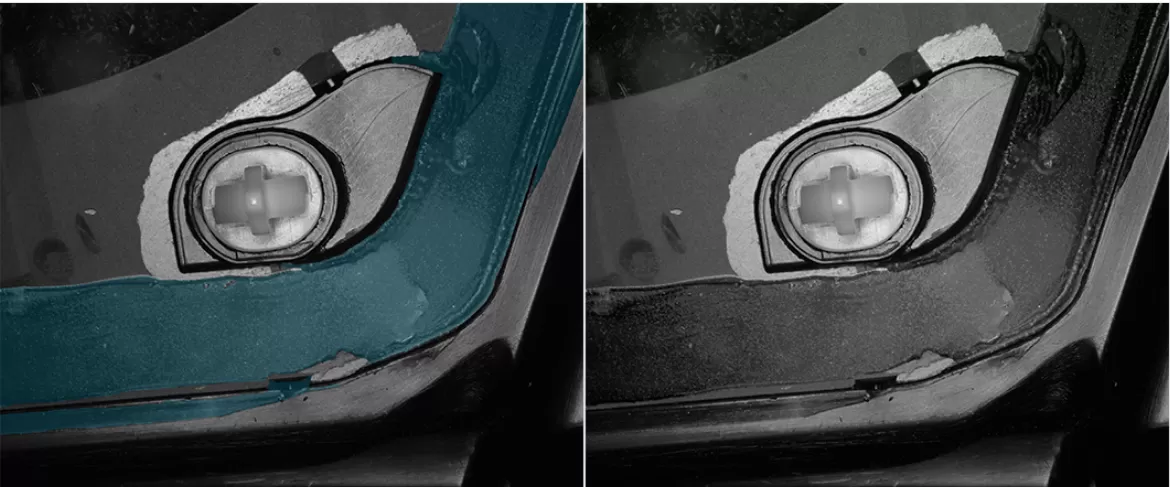

Employing our camera technology equipped with advanced techniques to enhance color representation offers a solution to this challenge. By manipulating the color spectrum, the camera can highlight imperfections on transparent surfaces that might be otherwise difficult to discern.