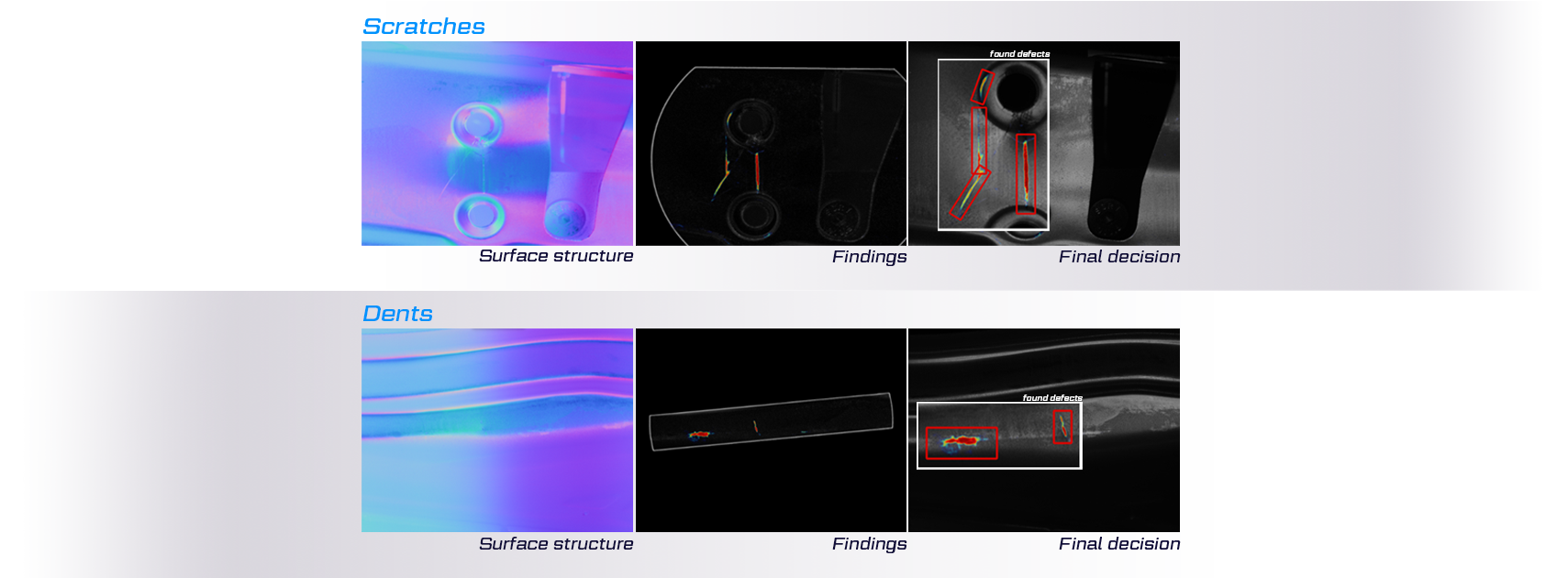

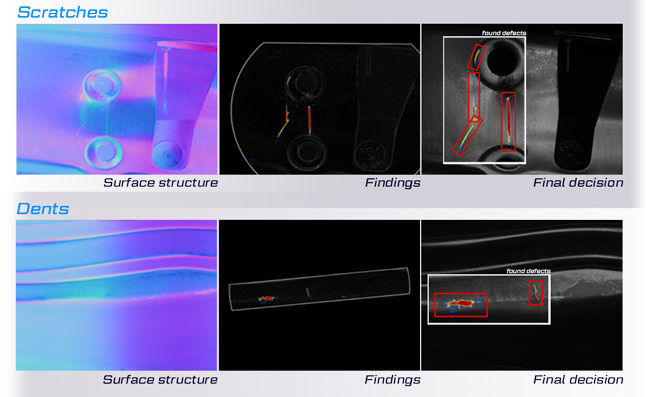

Solution for Complex and Shiny Pressed Metal Components

Inspecting pressed metal components is vital in ensuring product quality, particularly in the automotive and appliance manufacturing industries. However, it is not without its difficulties. The intricacies of pressed metal parts, which often feature complex shapes and fine details, pose challenges in terms of consistent quality control.

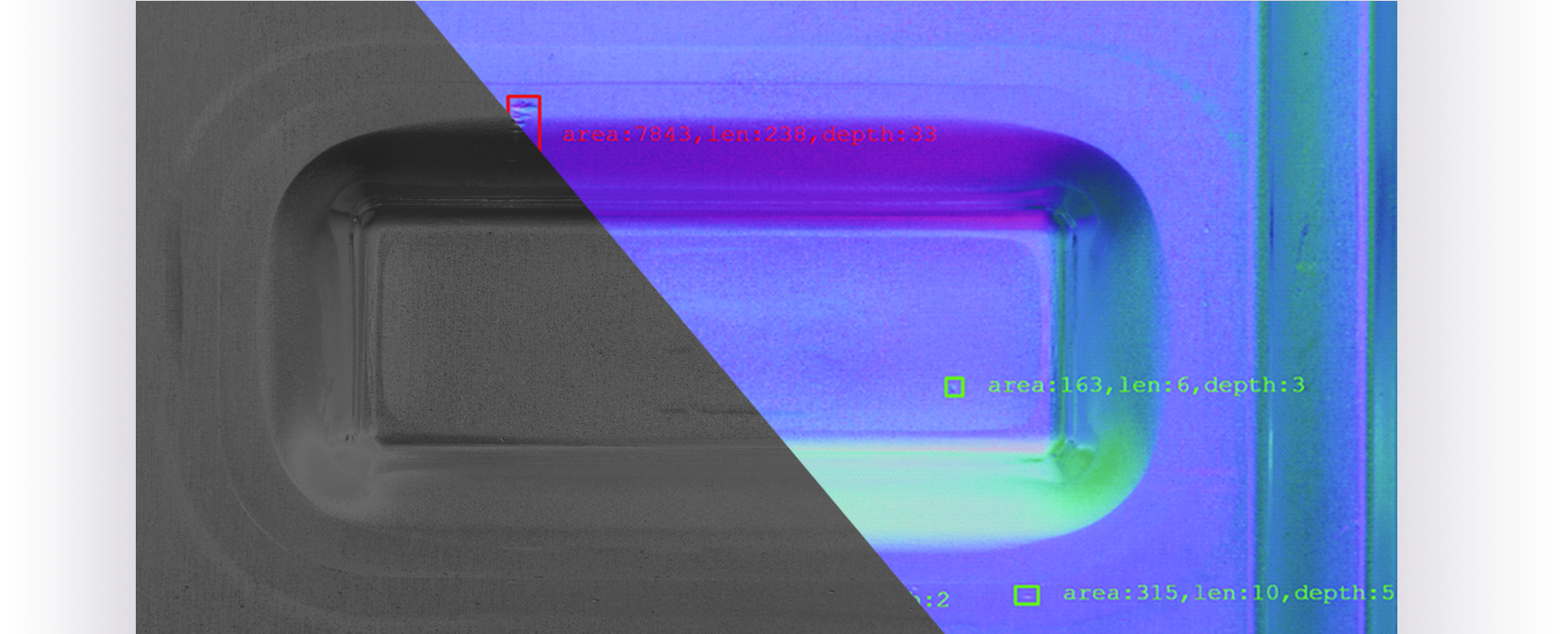

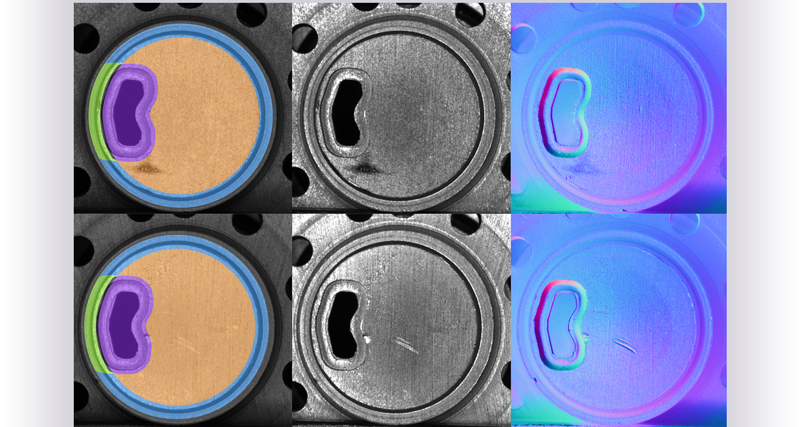

Sanezoo UNITY employs cutting-edge imaging technology and sophisticated algorithms to identify a range of common defects that might otherwise go unnoticed. Whether it's imperfections like scratches, dents, inclusions, or more subtle issues, SANEZOO UNITY ensures that even the smallest defects are pinpointed with exceptional precision.