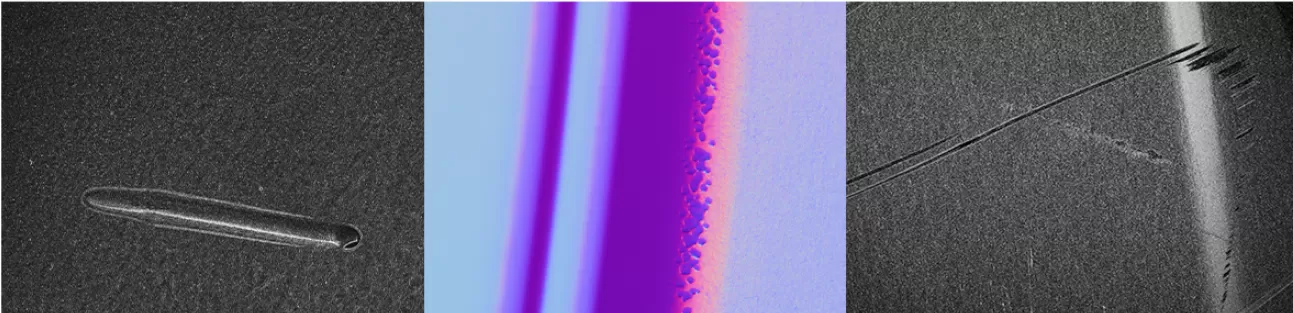

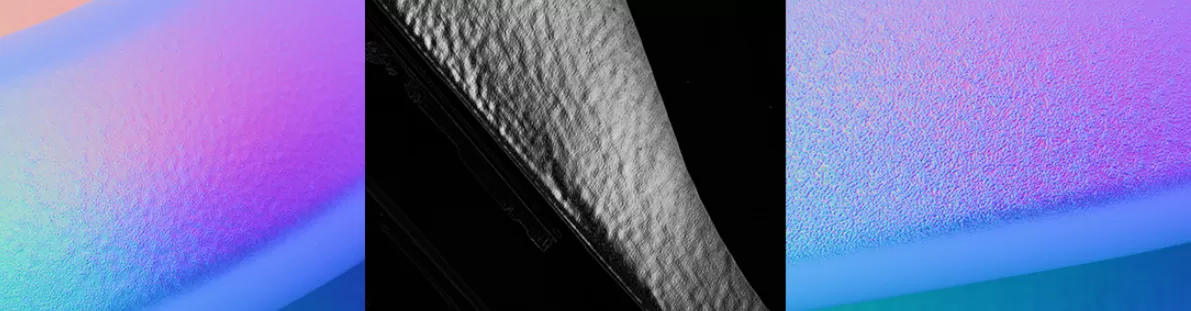

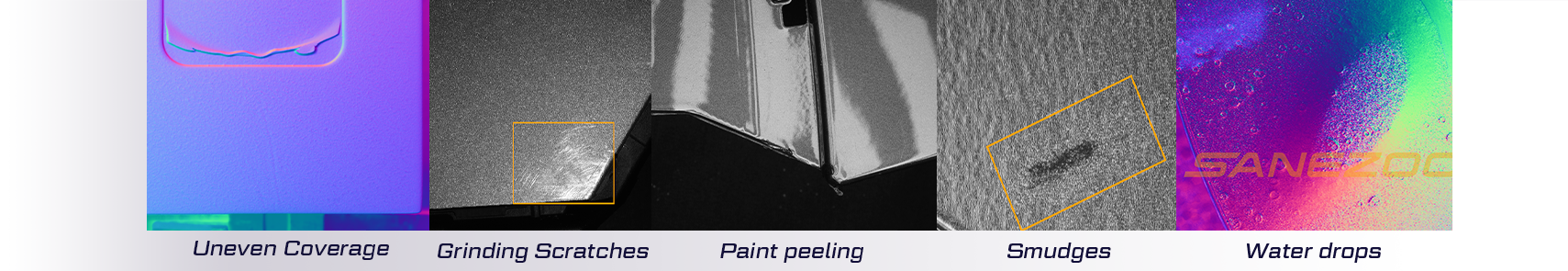

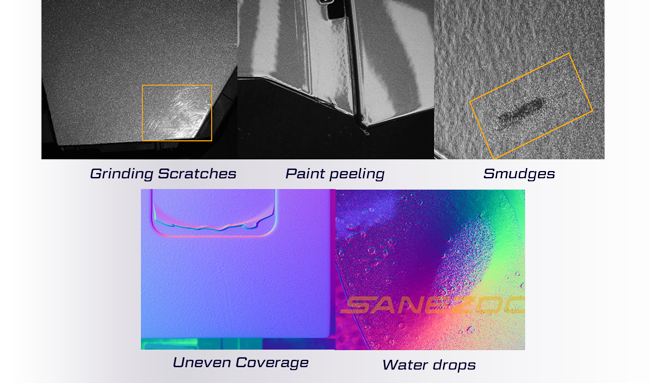

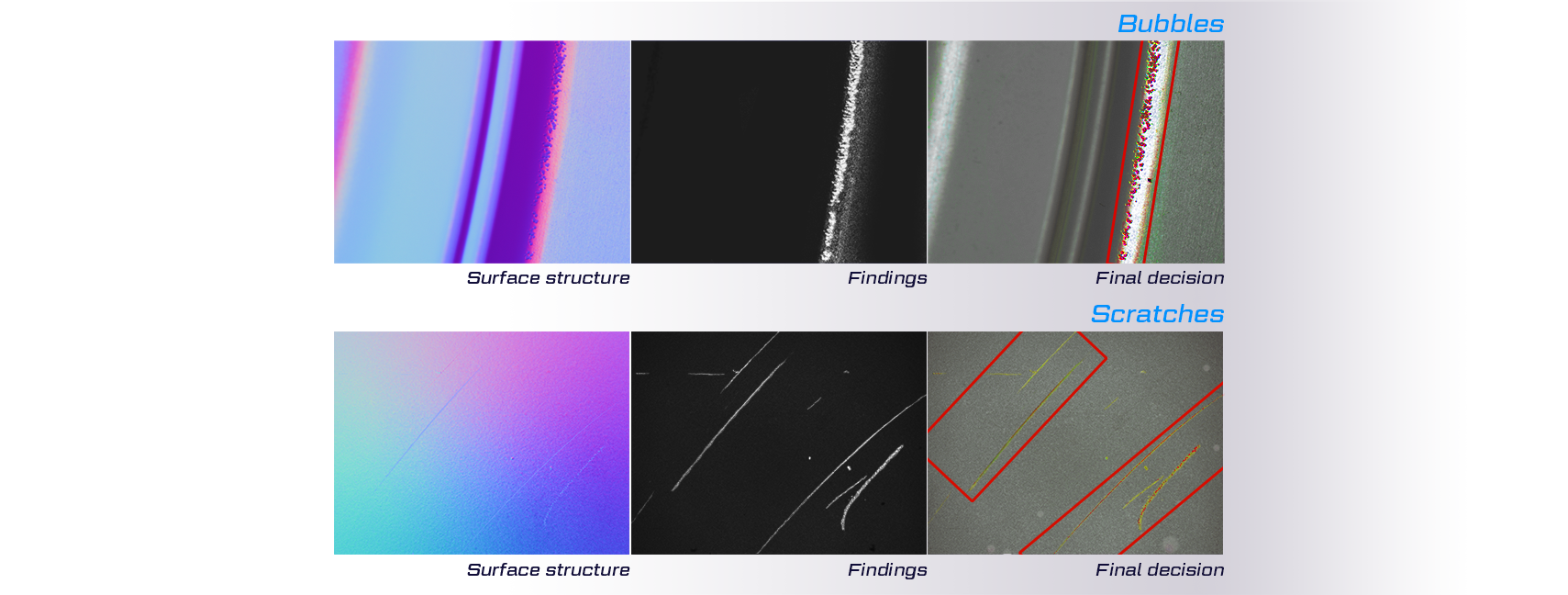

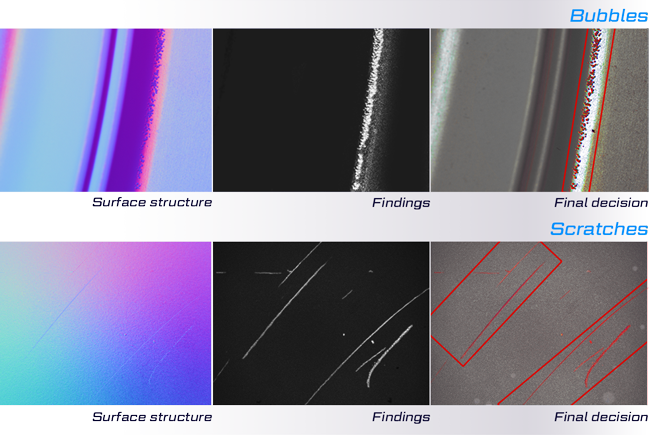

Different Colors. Metallic or Mate. Reliably Identifies All Common Defects.

Inspections of painted, wet, or powder-coated materials are critical to guaranteeing the final product's quality, appearance, and performance. Product inspection is complex due to coating concealing defects, variations in coating quality, and the need for specialized inspection methods. Environmental factors can also impact results, making precision and adaptability crucial.