UNITY

Surface quality inspection

Surface quality inspection

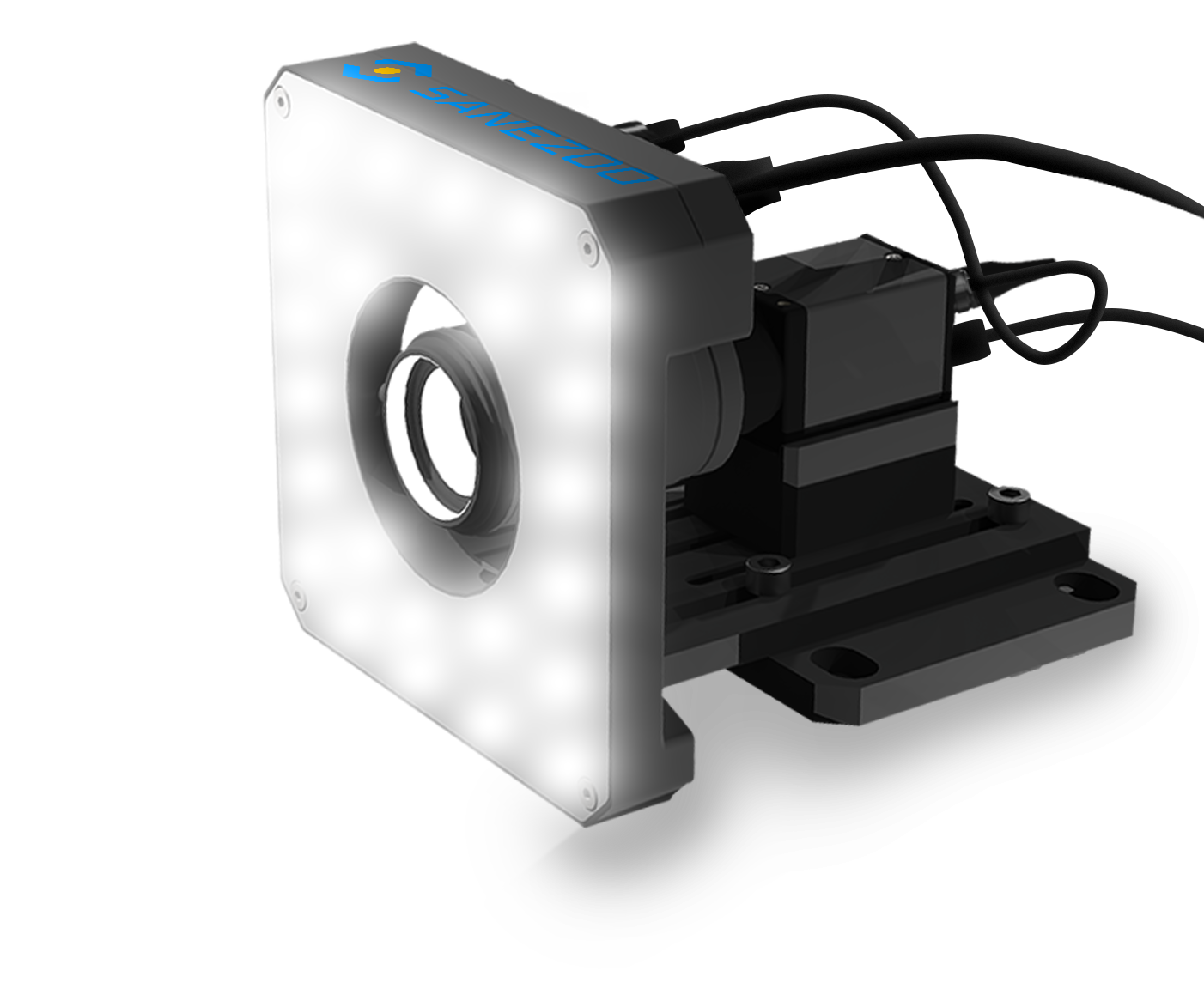

Unity is an innovative solution tailored for the manufacturing industry that sets a new standard for robust quality control. Equipped with proprietary hardware and software, our innovative Unity system provides unsurpassed accuracy and performance in product quality assurance.

Unmatched quality: Unity ensures excellent product quality control

while minimizing production costs.

Industry-tailored: Specifically designed for the manufacturing industry, it tackles specific quality control challenges.

Accuracy and reliability: Ensures consistent and reliable evaluation

under variable conditions, eliminating differences.

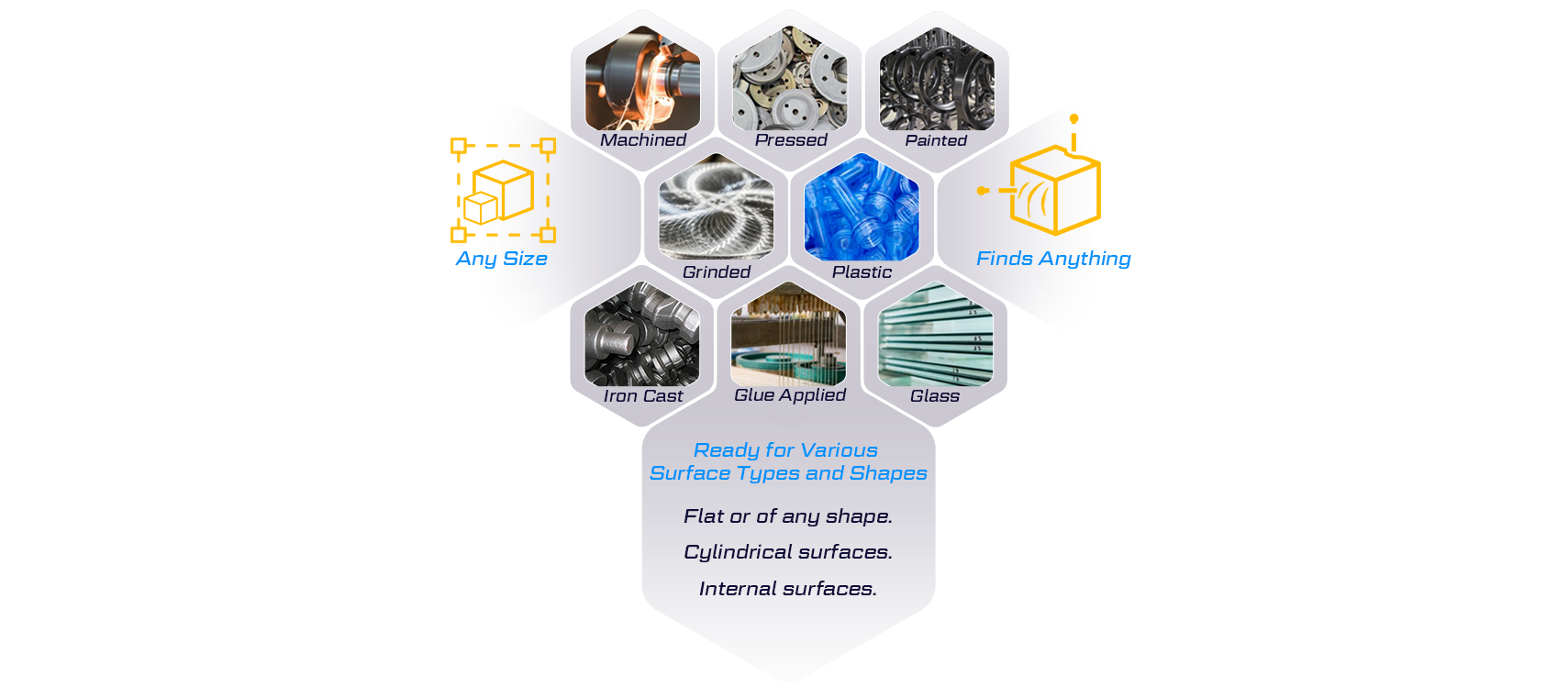

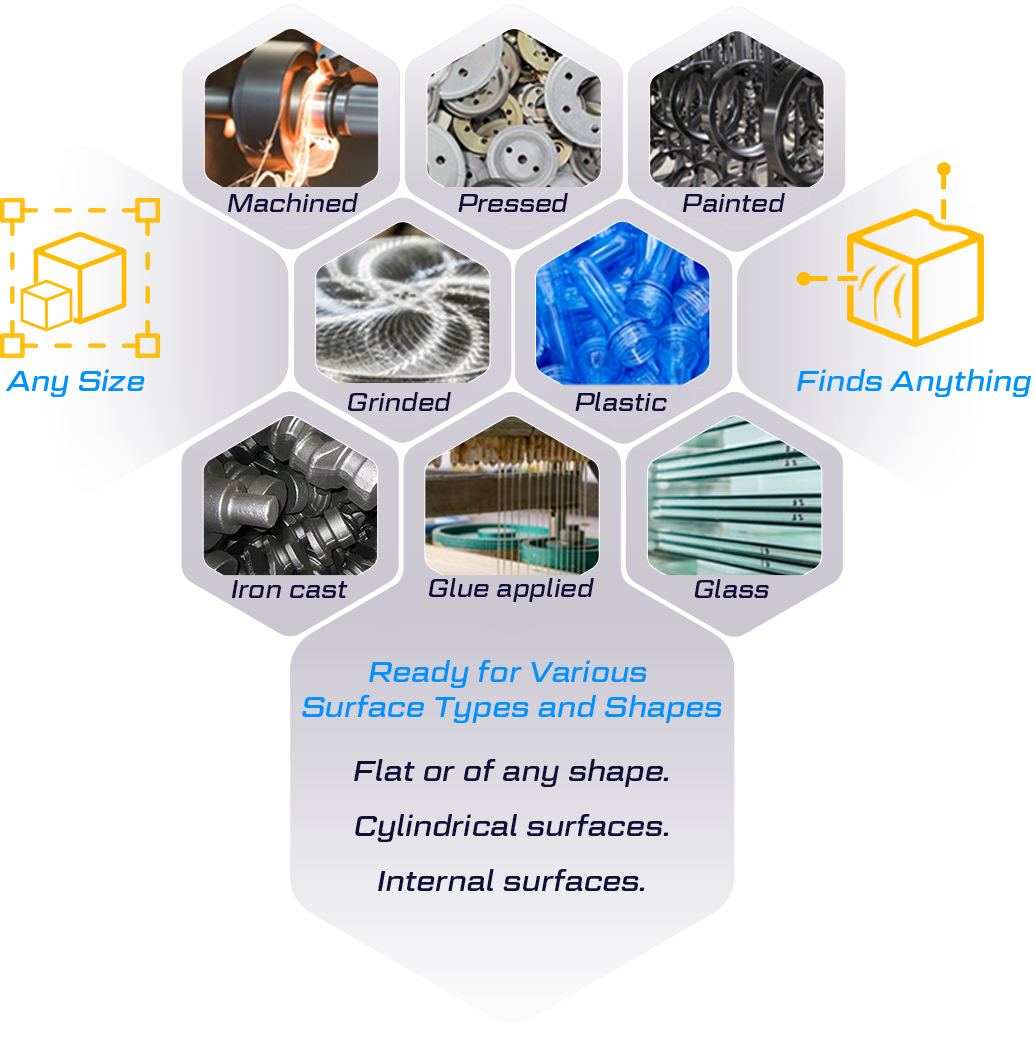

Equipped with a high-resolution camera to perfectly interpret every detail, even on the tiniest parts.

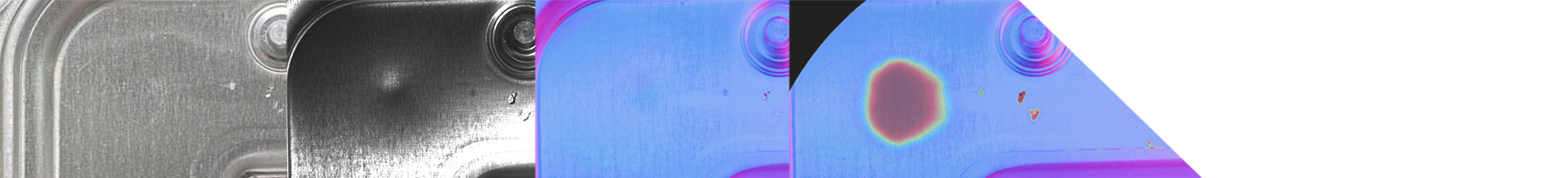

Prepared to automatically detect numerous defects with exceptional accuracy on various surfaces.

Smart decision engine guarantees a fast response while maintaining a low false alarm rate.

Resistant to imperfect positioning by manipulators, robots and automation mechanisms.

Resistant to ambient lighting. No problem with changing light.

Resistant to vibrations.

SANEZOO UNITY is a versatile solution for quality control on various surfaces, including shiny or matte materials, highly reflective surfaces like metal sheets, glass, and plastics, and it can detect imperfections of different shapes in random positions.

Please contact us and we will be happy to go through the solution options with you in detail. And if you want to test a specific sample from your production, you can send it to us for analysis and see the results on the spot.

Trusted by Industry Giants: Our Esteemed Partners and Clients

Please contact us and we will be happy to go through the solution options with you in detail. And if you want to test a specific sample from your production, you can send it to us for analysis and see the results on the spot.